Introduction

Lithium-ion battery fires — such as those in electric vehicles (EVs), electric bikes and scooters, and energy storage systems — are rare. However, when they do occur, they can be highly destructive and very difficult to extinguish. This is due to thermal runaway, a process of uncontrollable self-heating leading to high-temperature fires, that is characteristic of lithium-ion batteries.

Lithium-ion batteries are a critical component of the decarbonization of the energy and mobility sectors. However, the risks from lithium-ion battery fires are real, and new methods to manage such fires will be critical to avoid loss of life and property and to quell community concerns around EVs and energy storage systems. Luckily, thermal runaway can be stopped before it begins, and innovative methods are emerging that can predict thermal runaway and intervene to halt thermal runaway before it leads to a catastrophic incident. Although still in early stages, these solutions promise to further reduce the incidence of lithium-ion battery fires and significantly increase the safety of lithium-ion batteries.

Lithium-ion battery fires are rare, but can be extremely destructive

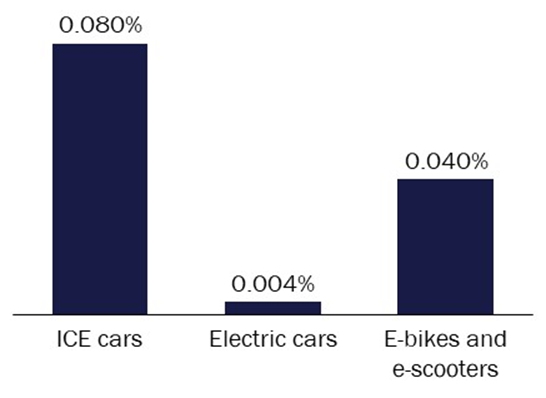

In the sea of news headlines, stories of lithium-ion battery fires often stand out, creating an impression of a significant, widespread issue. However, while such incidents are sensational and attention-grabbing, these fires occur less frequently than media coverage might suggest. An internal combustion engine (ICE) vehicle is 20x more likely to catch fire than a passenger EV. Electric 2 & 3-wheelers are half as likely to catch fire as an ICE car.

While lithium-ion battery fires are infrequent, their occurrence typically leads to extensive damage, disruption, and heightened media attention. Recent cases have highlighted several complexities which are unique to fires in lithium-ion batteries, such as the risk of reignition several hours after the initial fire has been extinguished, difficulty in containing lithium-ion fires by removing atmospheric oxygen or isolating external fuel sources, explosive venting of highly toxic gases, and the need for very large amounts of water to suppress such a fire. These complexities have left fire-fighting departments in several countries without a clear or effective response strategy in the case of a lithium-ion battery fire.

Electric 2 & 3-wheeler (bike, scooter, moped, rickshaw) fires are also a growing concern. While less frequent than internal combustion engine vehicle fires, electric 2 & 3-wheeler fires happen 10x more often than fires in passenger EVs. We believe that this can be attributed to the cheaper and more rudimentary battery management systems (BMS) common in electric 2 & 3-wheelers, which are not able to detect and prevent overcharging or battery overheating as effectively as more sophisticated BMS in passenger EVs. Fires in electric 2 & 3-wheelers also have a particularly high incidence of property damage and injury since 2 & 3-wheelers are often located in densely populated residential areas (e.g., underground garages or even stored inside homes).

Breaking down thermal runaway

The hazardous nature of lithium-ion battery fires primarily stems from a phenomenon known as thermal runaway, which refers to the unregulated self-heating of a lithium-ion battery. This occurs when the temperature within a battery’s cells exceeds safe operational limits, typically around 70°C. This elevated temperature initiates a chain reaction, causing the cathode materials to break down at temperatures between 200 and 300°C. This breakdown results in very high temperatures (e.g., reaching 900°C in Nickel Manganese Cobalt batteries), ignites flames, and triggers the explosive release of toxic gases, such as hydrogen fluoride.

Several factors can contribute to the overheating of lithium-ion batteries and thus potentially initiate thermal runaway. These include increases in ambient temperature, faults in the design of Battery Management Systems (BMS), manufacturing defects in the battery, and traumatic impact. Thermal runaway remains a risk for all types of lithium-ion batteries, although it is less energetic in lithium iron phosphate (LFP) cells than in nickel manganese cobalt (NMC) cells, and less energetic when the battery has a low state of charge (30% or less).

Containing lithium-ion battery fires is complex and challenging

When it comes to suppressing and preventing the spread of a battery fire once it has ignited, there are typically three approaches:

1. Smothering the fire that has spread outside the battery pack by displacing oxygen

2. Utilizing free radical trapping methods to extinguish the fire that has spread outside the battery pack

3. Cooling the battery pack to extinguish the fire within

Smothering agents

Smothering agents range from sand or fire-resistant crystalline glass materials to fireproof blankets. Though effective, blankets pose a risk as they can inadvertently increase the concentration of toxic gases emitted by the fire, thereby creating a greater danger for first responders. Other smothering substances include compressed carbon dioxide gas and powdered graphite, both of which produce a cooling effect, and an aqueous solution of vermiculite — a type of clay used to encapsulate the battery pack.

Free radical trapping agents

Free radical trapping agents typically involve carbonate salt, such as potassium carbonate, suspended in an aerosol. This reacts with and neutralizes free radicals like hydroxyl (OH), thereby halting exothermic combustion reactions outside the battery.

Of the above two fire-fighting methods, smothering agents such as compressed carbon dioxide gas and powdered graphite are particularly effective at containing lithium-ion fires once they’ve spread beyond the battery pack. Aqueous vermiculite, with its ability to absorb the toxic gases released by a battery fire and prevent localized gas buildup, also presents promising smothering capabilities.

Cooling agents

Cooling is the only confirmed method to extinguish a lithium-ion battery fire at its source. Among cooling agents, water remains the most effective, sustainable, and widely available choice. Other cooling agents, such as highly engineered non-reactive fluids like 3M’s Novec line, have also been utilized. However, due to their environmental impact — namely the highly toxic PFAS chemicals they contain — they are being discontinued by 3M from 2025.

Although water is the most effective cooling mechanism, lithium-ion battery fires need a very large amount of water for suppression — up to 80x more water is needed to suppress a passenger EV fire vs. an internal combustion engine fire. Recently, some solutions have emerged (such as the fine water mist solution developed by Cold Cut Systems), that significantly decrease the amount of water required to suppress a battery fire (from 80x down to 3x more than a passenger EV). These solutions are slowly being implemented in fire departments in Scandinavian countries, which have the highest adoption rate of EVs.

Once a lithium-ion battery fire has been extinguished at the source, it is vital to prevent re-ignition. This is achieved by submerging the battery in water or a saline solution. This process continues until all battery cells uniformly reach temperatures of 50–60°C, as verified by repeated infrared thermometer measurements — a process that can take up to a full day. Without such measures, burned lithium-ion batteries can reignite in impound lots, salvage yards, garages, or landfills, causing even more destruction.

The challenges posed by lithium-ion batteries aren’t confined to their active use. Post-usage, there’s a pressing and often overlooked issue: the environmental and safety risks stemming from battery disposal. While the combustibility of batteries is rare during their operational phase, improper disposal in regular landfills or waste streams can inadvertently elevate the risk of fires. It’s not uncommon for discarded batteries to cause landfill fires. In fact, 70% of landfill fires are caused by improperly disposed lithium-ion batteries in the US. Battery fires also risk releasing hazardous materials into the environment. This accentuates an urgent need for innovative solutions that facilitate the safe disposal and effective recycling of lithium-ion batteries.

Effective prevention is the key

In part, because lithium-ion battery fires are so difficult to suppress, the best way to address them is often a proactive approach — intervening before the fire starts, not after.

It can take up to 28 hours for a battery’s temperature to rise from normal operating temperature to 200–300 °C, which is the critical point after which flames and explosive venting of gases can occur in a few minutes. It is within this critical ~28-hour window that intervention can avoid a lithium-ion battery fire.

Given the destructive nature of lithium-ion battery fires and the complexities in suppressing them, innovative solutions are emerging to detect and preempt thermal runaways at their nascent stages. These strategies aim to predict, detect, and proactively intervene, ensuring that thermal runaway never gains a foothold. Notably, no single solution holds the magic bullet to this challenge. Instead, a combination of diverse approaches and technologies is arising, each addressing different facets of this problem.

· Accure uses predictive analytics on vast amounts of operating data to predict battery failure. Through mathematical models and predictive analytics, ACCURE can filter out noise and generate analysis from time-series data about cell-level voltage, current, and temperature. This enables ACCURE to identify the risk of safety-critical events (e.g., thermal runaways) days or weeks in advance.

· Qnovo uses edge computing and battery aging models to detect battery defects (such as excessive aging) and predict potential battery failures and thermal runaway. Qnovo can detect faulty batteries and provide 5–6 weeks’ notice before a fire occurs.

· Li-Ion Tamer has developed sensors that detect off-gassing prior to thermal runaway. The company’s sensors can detect early signs of thermal runaway (around 5 minutes before rapid self-heating begins) to allow for action to be taken to prevent a fire.

· Safire has developed a solution utilizing a non-Newtonian fluid — a liquid that solidifies under impact — that instantly transforms the battery from a liquid to a solid state, rendering batteries inert and preventing thermal runaways resulting from collisions.

Conclusion

Lithium-Ion battery fires are less common than fires among internal combustion vehicles, but they are often more damaging and difficult to suppress. A concerted strategy to tackle this challenge should include the following:

· Enhanced battery management systems and data & analytics to anticipate battery degradation and pull batteries out of service before they are likely to cause problems.

· Sensors designed to detect thermal runaway in its early stages combined with mitigation capabilities that can intervene on an emergency basis to prevent catastrophic failure.

· Further research on clever intervention strategies such as Safire.

· Better development and dissemination of suppression technologies and strategies to deal with the fires that will inevitably occur in spite of the best combination of all of the above.

About the Authors

Asad Hussain is the Partner of Research at MIP. Asad previously led PitchBook’s research coverage of the mobility sector, and his research has been featured in several premier media outlets.

Cassidy Shell is a Senior Associate of Strategy & Research at MIP. Cassidy was previously a Senior Associate at the Cleantech Group, where she focused on mobility and sustainability research.

Shweta (Shay) Natarajan is the Partner of Strategy at MIP. Shay has previously held strategy leadership roles at Caterpillar, McKinsey & Co., and Apple.

All authors have equal contributions and are listed alphabetically by first name.

MIP is a collaborative strategic investment firm that brings together the leading stakeholders in the mobility ecosystem — auto companies, parts suppliers, energy companies, fleet operators, logistics providers, technology and communications companies, financial and insurance companies, as well as cities and municipalities — to identify common challenges, find solutions, invest in those solutions, and then scale those innovations across the market